Optics on Submount / Metallization / Optomechanics / Active Alignment

Exhibitor

PHOTONICPARTS

Robust optomechanics and optics on submounts

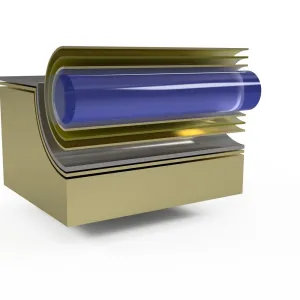

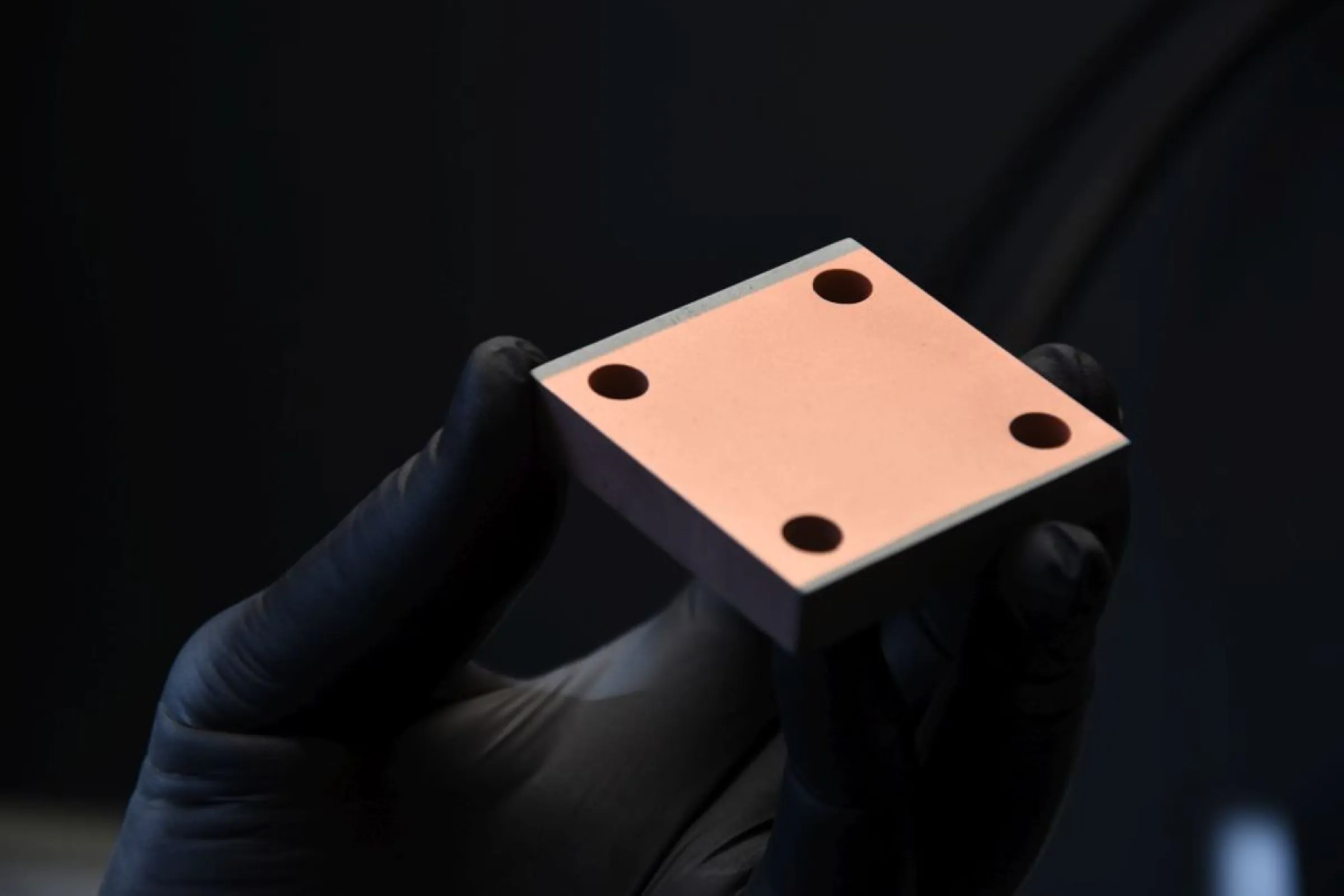

By utilizing flux-free soldering and CTE-matched submounts, our optomechanical assemblies enable low-stress mounting of optical components, ensuring long-term stability and high optical quality. This approach is particularly suited for deformation-sensitive elements, such as thin optical plates where wavefront planarity must be preserved. Additionally, the soldered, adhesive-free interfaces offer minimal outgassing, making them ideal for UV applications and contamination-sensitive environments. Our modular design allows for straightforward adaptation to different optic sizes and geometries.

Metallization service for optics, ceramics, metals

Application of solderable metallizations

partial metallization of optics

PVD application of different solder materials

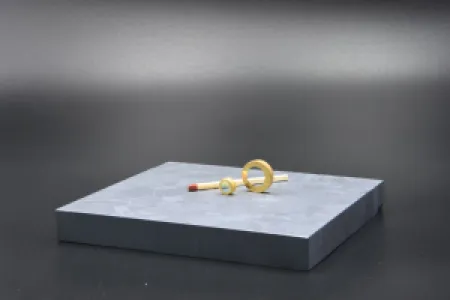

High precision flexure mirror mounts with soldered CTE-matched optic interface

Our SFM mirror mounts feature monolithic bodies with optics soldered via CTE-matched submounts for maximum mechanical and thermal stability. The flux-free soldering process ensures stress-free, long-term reliable bonding without adhesives. This design enables robust, vibration-resistant alignment – ideal for high-stability beam delivery in demanding environments.

Excellent pointing stability over changing conditions (Very low angle change (<20μrad in both axis) after multiple ΔT=60K temperature cycles

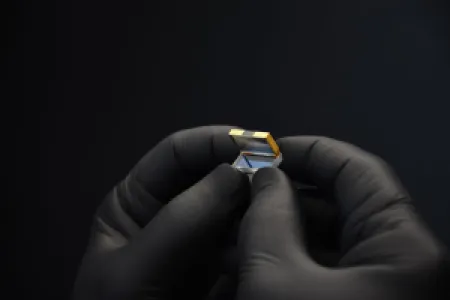

Optical component soldered on CTE-matched submount to reduce thermomechanical stress

Ultra compact design; minimal footprint

Vacuum compatible

Easily adaptable to different mirror dimensions

Optical components for machine-assisted assembly

Our active alignment technology enables us to achieve repeatable, consistent positioning of optical components in a molten solder interface. Local remelting using integrated heaters allows us to fix optical elements permanently and, stress-free fixation – without raditional mounts. The result: compact, robust, and precisely aligned optical systems.

Repeatedly adjustable in liquid solder

Fully integratable in machine-assisted automation setups

Completely glue-free, UV/vacuum/spacecompatibility

Integrated heater and temperature sensor

Application of solderable coating layers