Printoptix GmbH

Booth number: 4205-36

printoptix.com/

About us

Printoptix designs, develops, and fabricates unique micro-optical components on a scale from 2 µm to 4.5 mm and on a variety of substrates such as optical fiber tips, image sensors, or LEDs. Printoptix offers the whole process—from the customer's idea for a micro-optical part to the finished and optimized product and even series production—under one roof. With over 10 years of experience in 3D-printing micro-optical components, the company has developed a deep understanding of the challenges and especially the possibilities in designing and manufacturing micro-optical components and systems.

Address

Nobelstr. 15

70569 Stuttgart

Germany

E-mail: sales@printoptix.com

Phone: +49 157 85006381

Internet: printoptix.com/

Contact person:

Products & Services

Printoptix offers very individualized products and processes. We can take you through the whole development of your specific micro-optical systems for your applications - from the design of the optical components and simulation of the performance through extremely quick prototyping (prototypes can be done in a matter of days) all the way to 3D-printing series production of your optical systems.

We also offer off-the-sheld products such as micro objective for imaging on sensors or patchcables with integrated beamshapers. These can be easily be modified for your needs. If you for examoke beed a different beamshaoe or a specifiy substrate - yjst let us know, we are happy to find an individual solution!

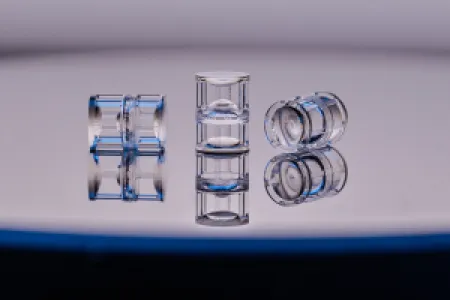

Micro Objective Lenses

Custom all-aspheric imaging objectives in the smallest possible form factors.

Perfectly aligned all-freeform lens stacks.

Our entirely new approach to lens fabrication leads you to optical solutions that were previously unthinkable.

Shortest development cycles thanks to 3D printing.

First prototypes in two weeks.

Ramp up to series production within one month.

Specifications

Size Ranges: 100 µm to 5 mm, very short variants possible

Freeform surfaces that are inherently alignment free

Field of view range: 10° – 160°

Surface roughness < 10 nm RMS

Shape errors: less than diameter/1000 PTV

Direct integration of black apertures and baffles

Custom geometry adaptions

Biocompatible polymers that are longterm stable and autoclavable

Highly transparent

Printing on sensors with < 1 µm alignment precision in x, y, and z

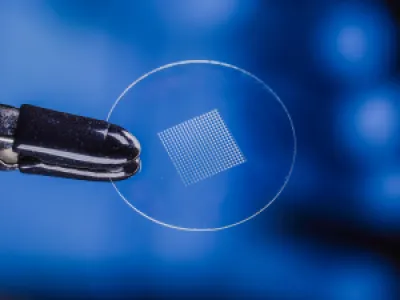

Fiber Tip Optics

Powerful optical components perfectly aligned to the fiber mode field.

Our approach of direct fabrication on the fiber tips anables highly precise fiber optical systems.

Specifications:

Optical quality with feature sizes <1 µm

Freeform, segmented or diffractive surfaces

Surface roughness <10 nm RMS. Shape errors <diameter/1000 PTV

Custom integration of absorbing structures and encapsulation

Direct integration of optics into common fiber connectors

Highly transparent material with low fluorescence

Biocompatible optics

Direct alignment to fiber mode field with <1 µm precision

Examples:

-thumb.webp)