Fraunhofer Institute for Laser Technology ILT

Booth number: 4205-26

www.ilt.fraunhofer.de/en.html

About us

Fraunhofer Institute for Laser Technology ILT

With more than 530 employees and more than 40 spin-offs, the Fraunhofer Institute for Laser Technology ILT in Aachen is one of the leading contract research and development institutes in its field. For 40 years, the Fraunhofer ILT experts have been developing and optimizing laser beam sources and laser processes for production and metrology, energy and mobility, medical and environmental technology, as well as quantum technology.

Address

Steinbachstr. 15

52074 Aachen

Germany

E-mail: info@ilt.fraunhofer.de

Phone: +49 241 8906-0

Internet: www.ilt.fraunhofer.de/en.html

Contact person:

Hans-Dieter Hoffmann

Head of Department of Laser and Optical Systems

E-mail: photonics-west@ilt.fraunhofer.de

Phone: +49 241 8906-0

Dr. Patrick Baer

Group Manager Fiber Lasers

E-mail: photonics-west@ilt.fraunhofer.de

Phone: +49 241 8906-0

Dr. Achim Lenenbach

Head of Department of Laser Medical Technology and Biophotonics

E-mail: photonics-west@ilt.fraunhofer.de

Phone: +49 241 8906-0

Dr. Christian Vedder

Head of Department of Surface Technology and Ablation

E-mail: photonics-west@ilt.fraunhofer.de

Phone: +49 241 8906-0

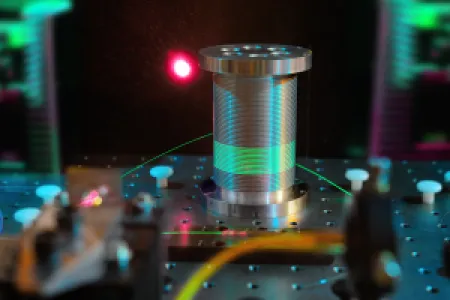

Fiber Lasers

Fiber lasers combine highest beam quality and effi ciency, both in continuous and pulsed operation. These lasers have established themselves in industrial applications alongside gas and solid-state lasers and have partially replaced them since they can be designed monolithically and, therefore, very robustly without needing free-space components. Thanks to its high flexibility of output parameters, such as power, wavelength or pulse shape, fiber lasers can be used for a wide range of applications: in material processing, e. g. for ablation and welding, interferometry in metrology, or in medical technology.

Optical Systems

In “Optical Systems,” Fraunhofer ILT focuses on providing its partners with considerable expertise in beam shaping and beam guiding, frequency conversion as well as in design, layout and packaging of optical components.

Commercial and self-developed software tools are used to design or optimize optics. With special algorithms, Fraunhofer ILT designs optical free-form surfaces so that the industry can manufacture them later with laser-based processes. Modern diffractive or refractive optical elements, for example, can bring light into almost any shape by means of adapted diffraction structures. Complex beam profiles or patterns can be realized as well as a distribution of the energy of a beam to a whole array of similar partial beams. Integrated into new laser systems, the optical systems Fraunhofer ILT develops enable increased productivity compared to conventional techniques, even in precision manufacturing on the micrometer scale.

Fraunhofer ILT is developing scanners that can deflect laser radiation very quickly and at high precision, and apply it specifically to workpieces. The institute either adapts commercially available scanners to specific applications or develops new systems for drilling, ablation, cutting, welding, additive manufacturing or metrological tasks.

Surface Technology

In “Surface Technology,” Fraunhofer ILT focuses on developing laser-based technologies for the efficient processing, functionalization and finishing of surfaces.

Thin films are used for electronic applications, for wear and corrosion protection as well as for optical and structural applications. Since lasers have specific advantages – they are locally selective, have inline capability as well as placing a low thermal load of the workpieces – they open up many new possibilities in designing new production processes and components in which functionalities can be integrated.

Component condition data, such as thermal and mechanical loads, can be collected by special sensors and form a basis for predictive maintenance, big data and AI approaches in production. Fraunhofer ILT combines various manufacturing methods, for example, to equip printed lightweight components with appropriate sensors. By combining Laser Powder Bed Fusion with digital printing and laser post-treatment processes, the institute is paving the way for the production of “sensing” components.

Thanks to their functionality, structured surfaces contribute, for example, to minimizing friction in combustion engines, to increasing efficiency in lighting systems or to improving the activation of chemical processes in fuel cells. Surface properties also play an important role as a quality feature of products.

Medical Technology and Biophotonics

Not only can a large number of diagnostic and therapeutic applications be optimized through the use of laser technology, but they become possible in the first place. As a non-contact instrument, light offers great advantages, both in the manufacture of corresponding instruments and in diagnostics itself.

For surgery, wound treatment and tissue therapy, Fraunhofer ILT is developing lasers with adapted wavelengths, microsurgical systems and new laser therapy methods in close cooperation with partners from the life sciences sector. In microsurgery, novel measurement methods based on optical coherence tomography (OCT) are used. Together with experts in neurosurgery, the scientists at Fraunhofer ILT are developing laser-based solutions to reduce, for example, the psychological stress and the risk of injury for patients during operations.

With the help of laser processes such as joining, structuring and functionalization, application-adapted lab-on-a-chip solutions can also be implemented, which, for example, make rapid multiplex diagnostics possible and can be used for point-of-care diagnostics.

Patient-specific implants can be manufactured using Laser Powder Bed Fusion or laser-based stereolithography. Additively manufactured high-resolution and biocompatible scaffold structures for novel implants are used, for example, in regenerative medicine or in the field of organoid test systems in the pharmaceutical industry.