AIXEMTEC GmbH

Booth number: 4205-43

www.aixemtec.com

About us

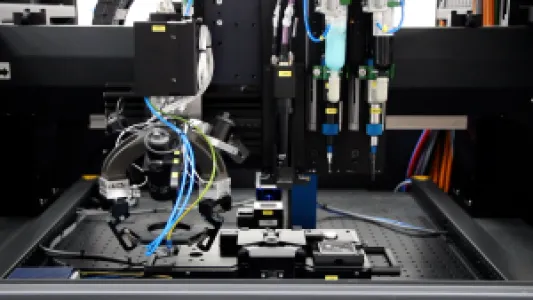

AIXEMTEC GmbH develops and manufactures standardized machine platforms for assembly and test automation in photonics.

Our modular systems combine active alignment, precision bonding, optical inspection, and metrology within one scalable architecture.

With the PhotonBeast product family, AIXEMTEC enables customers to scale seamlessly from R&D to high-volume production, using identical hardware modules and process building blocks.

All machines share an open software environment that allows customers to integrate their own code, sensors, and IP – ensuring full process transparency and control.

As part of the Schunk Group, AIXEMTEC provides global support and industrial reliability, serving leading companies in telecom/datacom, laser systems, sensing, and quantum photonics.

Address

Kaiserstr. 100

52134 Herzogenrath

Germany

E-mail: info@aixemtec.com

Phone: +49 2407 9538480

Internet: www.aixemtec.com

Contact person:

Tobias Müller

CCO

E-mail: tobias.mueller@aixemtec.com

Sebastian Sauer

CTO

E-mail: sebastian.sauer@aixemtec.com

Arne Bentfeldt

E-mail: arne.bentfeldt@aixemtec.com

Products & Services

AIXEMTEC is a company that specializes in the development and production of high-precision assembly and test machines. We combine know-how for highest motion resolution, ultra-precise dispensing, metrology and active alignment. On top of that we developed flexible modular and scalable machine architectures for handling optics, wafers, and fibers on several automation levels. By offering prototyping, process development and small-series manufacturing up to mass production services we solve multiple issues in production automation projects.

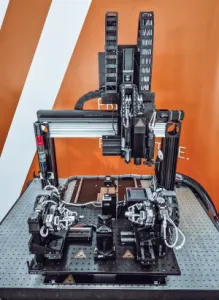

PhotonBeast Product Family

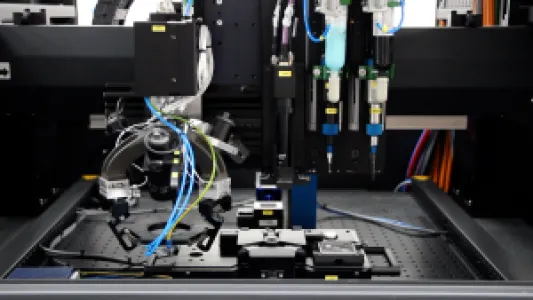

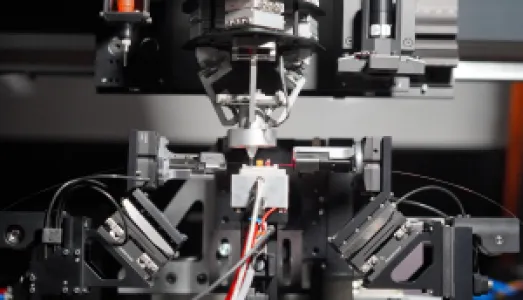

The PhotonBeast is AIXEMTEC’s modular platform for scalable photonics assembly and test automation.

It combines standardized hardware modules and process building blocks for fiber attach, laser assembly, and PIC packaging.

Users can scale seamlessly from laboratory setups to full production lines using the same software, interfaces, and machine components.

Key benefits:

• One platform for R&D to high volume production

• Modular hardware and open software architecture

• Compatible with laser, fiber, and PIC applications

• Proven <50 nm post-bond accuracy

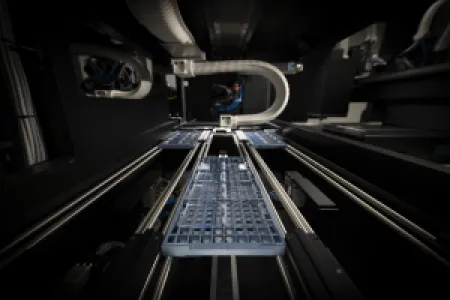

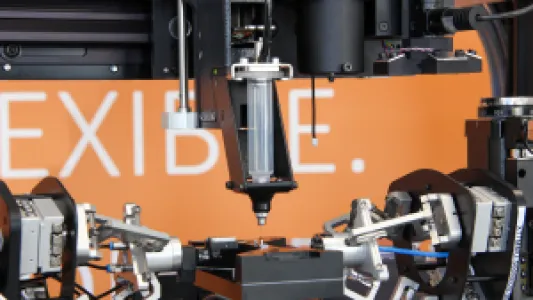

Flaixline – High-Volume Photonics Production Platform

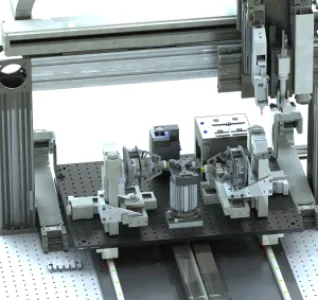

The Flaixline is AIXEMTEC’s scalable machine platform for parallelized photonics production at industrial volumes.

Designed for maximum throughput without compromising alignment precision or yield, the Flaixline architecture decouples precision process stations from high-speed material logistics using intelligent load balancing strategies.

It supports multi-product workflows and simultaneous processing across multiple alignment, bonding, and testing stations. Integrated with autonomous loading systems (e.g. wafer, tray, tape), it enables true lights-out manufacturing.

Key Features:

• Parallel processing across multiple assembly lanes

• Active alignment with <50 nm post-bond accuracy

• Integrated optical inspection, metrology, and curing

• Scalable logistics with contactless part transport

• Configurable for FAU attach, PIC packaging, camera/lens assembly, or wafer optics

• Optimized for 24/7 operation with JEDEC, wafer, or frame carriers

Best fit for:

• PIC and fiber array production

• High-volume camera and laser modules

• Wafer-level micro-optics processing

• Inline testing and grading for binning

The Flaixline redefines photonic manufacturing scalability – enabling mass production without sacrificing precision.

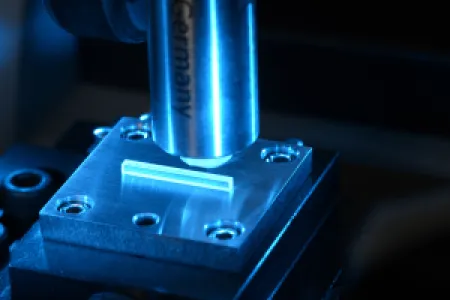

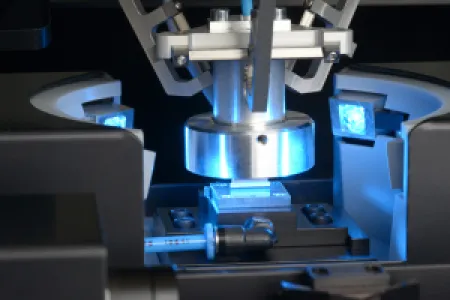

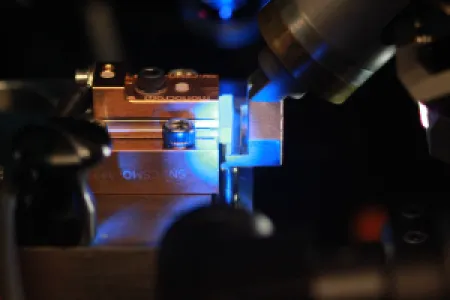

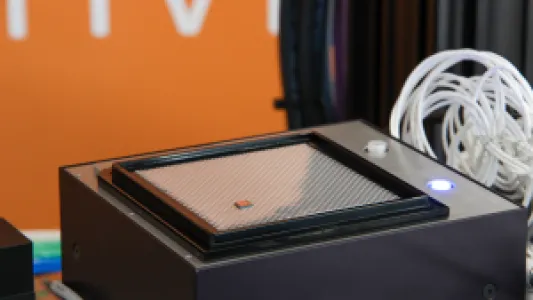

Lens and MLA Attacher

The Lens Attacher automates precision lens placement and bonding for laser and camera systems.

It supports active optical alignment, adhesive dispensing, and UV curing with shrinkage compensation.

The integrated metrology system ensures sub-micron positioning and repeatability across product variants.

Key features:

• Active alignment of lenses and mirrors

• Integrated beam diagnostic and UV curing tools

• Machine learning-based pre-alignment and first-light detection

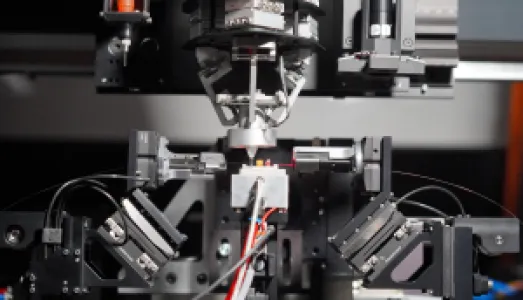

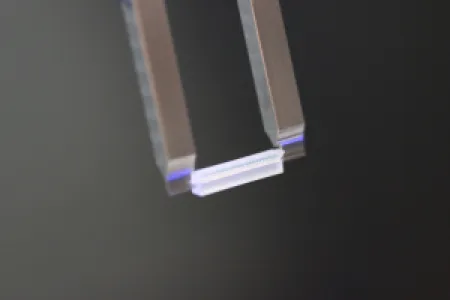

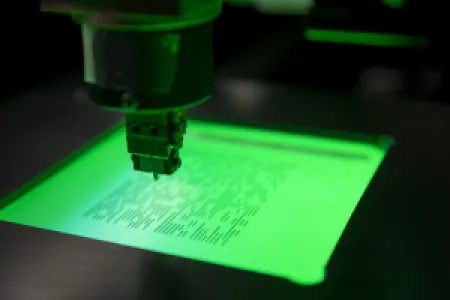

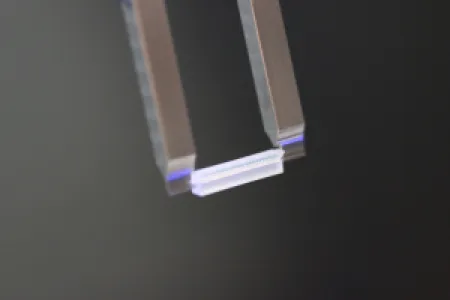

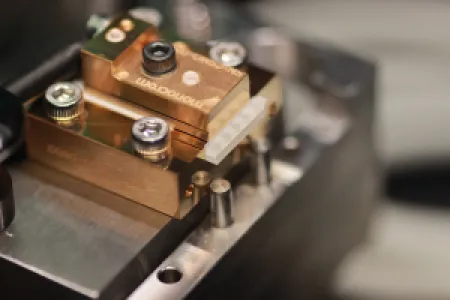

FAU / Fiber Attacher

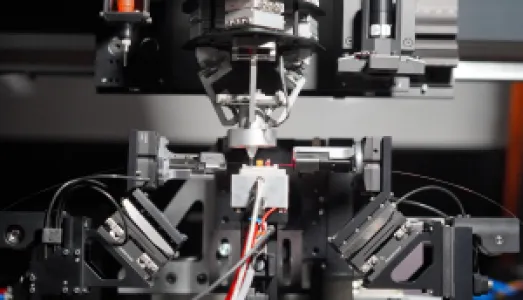

The Fiber Attacher enables active alignment and bonding of single fibers, fiber arrays, and FAUs to photonic components.

Its dual-sided alignment engine with 6-DOF micromanipulators achieves best-in-class coupling efficiency and insertion loss performance.

Highlights:

• Active alignment with down to 25nm precision

• Support for PM, SM, and multi-core fibers with edge and grating coupling

• Integrated power, wavelength, and beam-profiling sensors

• Flexible tray or wafer feeding options

5. Camera Assembler

The Camera Assembler automates optical alignment and assembly of imaging modules such as LiDAR, automotive, and industrial cameras.

It combines fast motion control, metrology, and precision dispensing to achieve high yield and short cycle times.

Key benefits:

• Active alignment of sensor and optics

• High-speed adhesive dispensing and curing

• Scalable from prototype to mass production