4JET Group

Booth number: 4205-19

www.4jet.de/

About us

4JET develops laser systems for the micromachining of glass and thin filmsm, as well as for surface preparation, cleaning and functionalization of sensitive technical surfaces.

Core markets include photovoltaics and technical glass processing, the tire industry and e-mobility, as well as the aerospace industry.

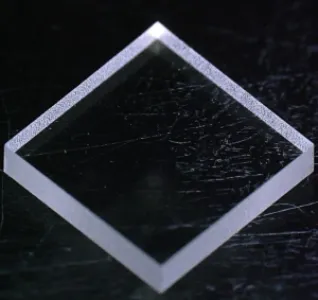

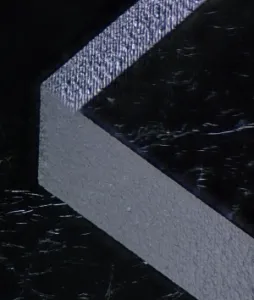

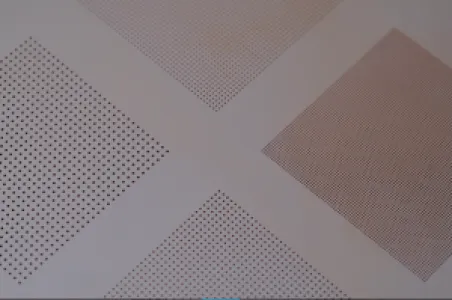

4JET offers the most advanced solution for high edge strength, small radii cutting of delicate glass parts. 4JET’s enP (enhanced nanoPerforation) process allows to control crack propagation in unmatched precision – enabling lowest edge roughness and an improvement in edge strength of over 60% compared to conventional ultrafast filamentation cutting

Since its foundation in 2006, the company has developed unique process technologies, such as high contrast tire sidewall markings and the LEAF technology for surface modification by laser interference structuring. It enables drag reduction of aircraft by mimicking the sharkskin effect.

Furthermore, 4JET has patented a range of laser processes for tool cleaning, surface preparation and product tracking.

The company employs around 240 specialists, including numerous engineers and scientists, at its headquarters in Alsdorf (Germany), the site in Krailling (Germany) and its subsidiaries in Atlanta (USA) and Shanghai (China). 4JET holds over 150 patents and intellectual property rights and regularly invests more than 10% of its turnover in research and development.

Address

Otto-Lilienthal-Str. 1

52477 Alsdorf

Germany

E-mail: info@4jet.de

Phone: +49 2404 92210

Internet: www.4jet.de/

4826 Folton Industrial Blvd SW

GA 30336 Atlanta

United States

E-mail: atlanta@4jet.de

Phone: +1 888 9794

Internet: www.4jet.de/

Contact person:

Dr. Antun Peić

E-mail: antun.peic@4jet.de

Phone: +49 2404 92210

Oliver Albrich

E-mail: oliver.albrich@4jet.de

Phone: +49 2404 9221-0

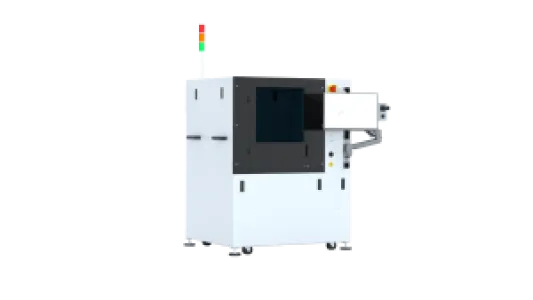

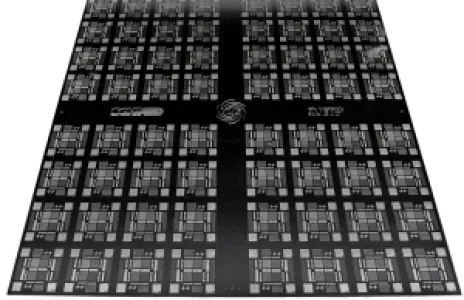

PEARL 400S

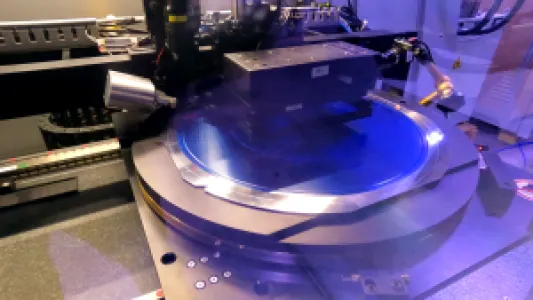

PEARL 400S – The Modular Solution for High-End Glass Processing

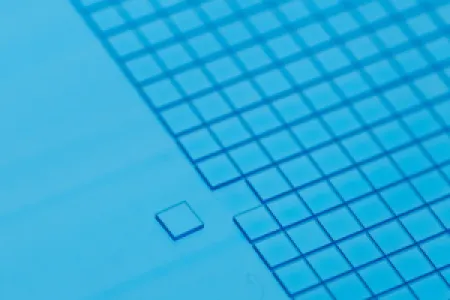

The PEARL 400S is a modular laser processing platform for glass wafers, glass substrates for the semiconductor industry, and other brittle materials. It is ideal for applications in microelectronics, optics, sensing, and AR technology – anywhere where the highest precision, process reliability, and cleanroom compatibility are required.

The platform is built on a highly stable granite gantry and is available in various configurations – each optimized for specific process steps such as nanoPerforation (Wafer Dicing, WD), thermal separation (WS), ablation, or microdrilling (Wafer Ablation, WA).

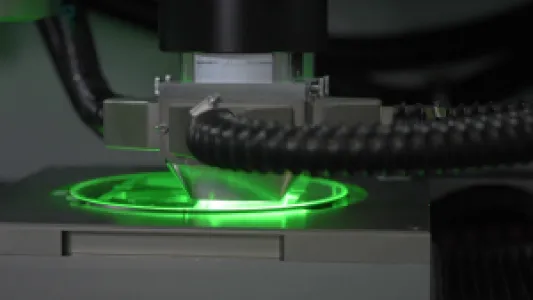

PEARL 500X

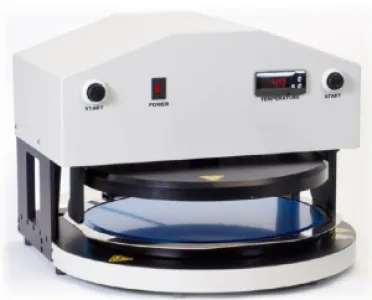

PEARL 500X – The All-in-One Solution for Precision Glass Processing

The PEARL 500X is a versatile laser system for processing glass wafers, thin glass, coated substrates, and other brittle materials. The platform combines multiple process steps – nanoPerforation, thermal separation, laser drilling, and marking – making it the ideal solution for research and development, pilot lines, and flexible production environments where maximum precision and process versatility are required in a compact footprint.

The platform is built on an ultra-stable granite gantry with linear motor axes and is designed for continuous industrial operation. By integrating multiple process heads into one system, it reduces floor space requirements, production line complexity, and investment costs.

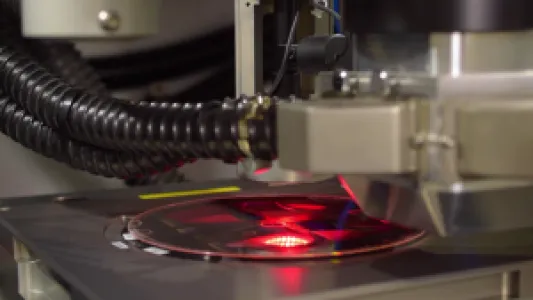

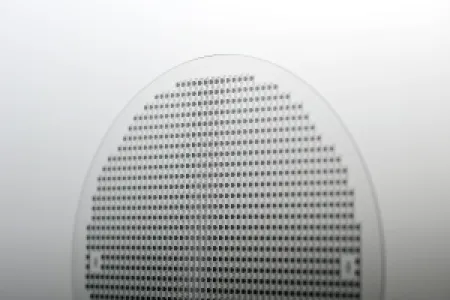

PEARL VLIS

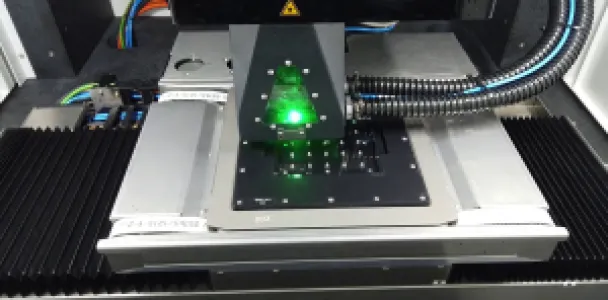

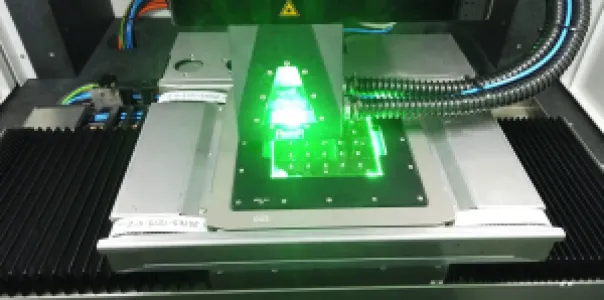

PEARL VLIS – Laser Processing Machine for Through Glass Vias and Volume Glass Structuring

The PEARL VLIS represents a new generation of ultra-precise laser processing machines, engineered for high-volume, high-accuracy glass volume structuring using our Volume Laser Induced Structuring (VLIS) process.

Branded under PEARL VLIS, this platform is engineered to meet the rigorous demands of Through Glass Via (TGV) manufacturing for advanced semiconductor packaging, µLED displays, MEMS, photonics, microfluidics, and sensor technologies.

With best-in-class precision, beam quality, and full compatibility with downstream processes like etching and metallization, PEARL VLIS sets the benchmark for next-generation glass processing.

DTX 200 NX

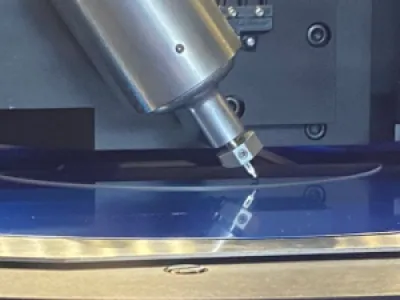

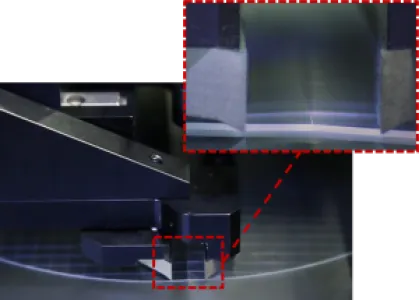

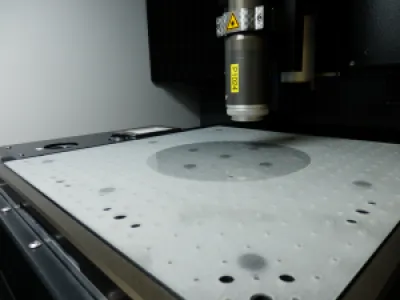

Wafer Dicing – Precise Scribe & Break with the DTX 200 NX

Precise wafer singulation is a critical step in the production of modern microtechnology. Whether in optics, sensor manufacturing, or general wafer processing: clean, low-stress break edges and maximum repeatability are essential.

With the DTX 200 NX, we offer a mechanical "scribe & break" system specifically designed for brittle materials – precise, reliable, and highly flexible.

-thumb.webp)

-thumb.webp)